Commercial and Industrial

Continuous Stainless can fabricate anything for your commercial facility / plant or workshop.

From constructing a fire water ringmain to high hygiene health and safety upgrades, we can manufacture to all to your specifications. We have specialist commercial fabrication expertise and are fully qualified in fabricating for the food manufacturing and dairy industries.

We can also fabricate those difficult one off items with our well equipped workshop which includes a CNC water jet cutter, guillotine and CNC brake press.

Piping

Stainless steel pipework to AS/NZ standards

Tank and vessel installation

Installation of specialist process equipment

Piping maintenance

Dairy, Chemical, Water Treatment & Wastewater

Chilled water line and compressed air line

Tanker wash pipework

Hygiene plant conduit

Flooring pump/pipework removal and reinstate

FEATURED PROJECT:

Lactoferrin Upgrade

Continuous Stainless worked on the commercial fabrication upgrade of Fonterra's Waikato Lactoferrin Plant. The $11 million upgrade of the plant is helping Fonterra to meet growing worldwide demand for the product, doubling its capacity to produce.

FEATURED PROJECT:

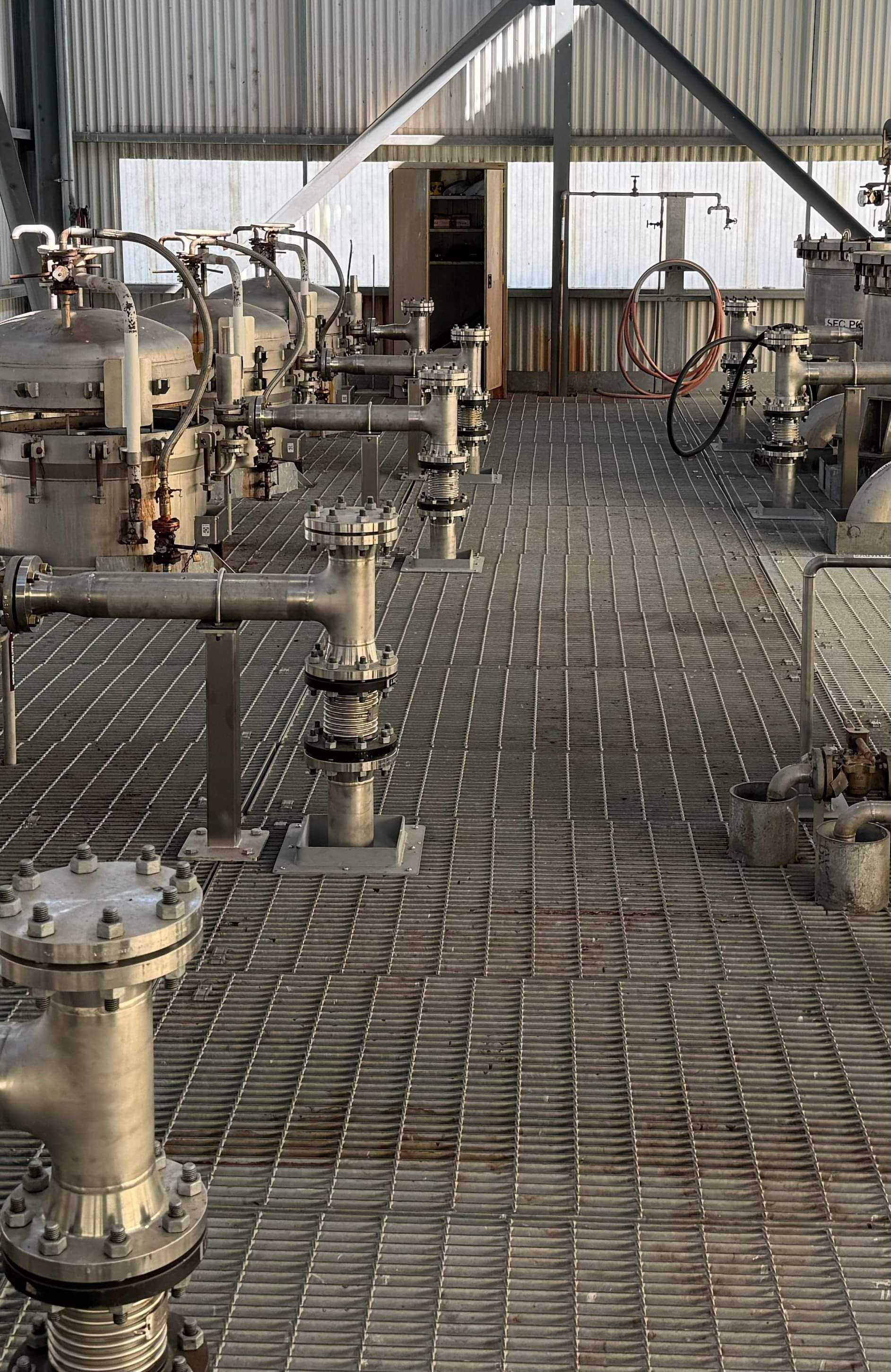

Pressure Relief Valve (PRV) upgrade

We completed a pressure relief valve upgrade project, involving site measure, commercial fabrication of parts in our workshop and on site installation. The work included install of nozzles into existing tanks on site and schedule 10 304 piping ranging from 40 NB to 200NB. This project was completed on time and under budget for our chemical plant client.

FEATURED PROJECT:

Fire-Water Ring Main

The fire-water ring main is a header network of pipes that transfers the water from the pumps to the fire. Continuous Stainless completed a fire water ringmain fabrication and fitout for Fonterra's Lichfield facility. First built in 1995, Lichfield is the Co-op’s second-largest cheese plant and houses one of the largest dryers in the world. The fire water ringmain project involved schedule piping fabrication of more than 350 metres of large stainless steel pipe.

FEATURED PROJECT:

High Hygiene Area Health and Safety Upgrade

Needing a health and safety upgrade of a High Hygiene area within their facility, a large food manufacturer engaged Continuous Stainless to complete their upgrade project. From site inspection through to design and install, 304 stainless steel was fabricated to comply with all high hygiene standards.

“Techo have worked with CSL on multiple projects over the last 10 plus years. Their dedicated team have always delivered their part of our project to a high standard of quality and safety. A lot of this work has been achieved under tight time frames and CSL haven't let us down.

We also appreciate the personnel and equipment that is on hand in their workshop as this compliments the installation work they undertake take for us.

It has been a pleasure to work alongside Dean, Lynette, James, Matai and the rest of the team. We will certainly continue our relationship with CSL.”

Ryan Mitchell, Construction Manager, Techo

"Continuous Stainless have worked on our projects for several years, they have consistently demonstrated a high standard of workmanship and professionalism. We enjoy working with the teams and look forward to doing many more projects together.”

FUTURIZE PEROXIDE – The peroxide experts at Evonik

Tim McPherson, Logistics and Facilities Manager

“We would like to extend our heartfelt appreciation to Continuous Stainless for their dedicated outstanding stainless steel pipework in our factory for the past 5 years. The team was professional and responsive, and delivered the project on time. Thank you, Continuous Stainless, for your exceptional service!!!”

Eric Leung, General Manager, New Zealand Quality Waters Ltd

"I am pleased to provide a testimonial for Continuous Stainless Limited, who have been engaged in projects at Fonterra Waitoa and Te Rapa for the past five years.

Throughout our collaboration, the Continuous Stainless team has consistently demonstrated exceptional professionalism, dedication, and a strong work ethic. Their performance has consistently exceeded our expectations, reflecting a commitment to quality and excellence.

Their adherence to Health and Safety standards is exemplary. Continuous Stainless always follows the necessary protocols for each work area, ensuring a safe environment for all involved.

Moreover, their vision and design skills are outstanding. They deliver solutions that not only function seamlessly but are also designed with usability and maintainability in mind. This level of foresight allows me to focus on other critical matters, ultimately saving me valuable time.

I highly recommend Continuous Stainless Limited for any project requiring a skilled and dependable partner, as their expertise and commitment to excellence are truly commendable."

Blair Bond, Senior Engineering Projects Manager

Uni Region – Waitoa and Te Rapa Sites, Fonterra Co-operative Group Limited

“We have had the pleasure of working with Dean and his team for several of our projects. Their attention to detail is unparalleled, the team is not only skilled but also incredibly professional and responsive. They consistently met deadlines without compromising quality, making them our go-to for all our fabrication needs. We highly recommend Continuous Stainless to anyone looking for top-notch services.”

Vaughan Hanna, Managing Director, Utrex